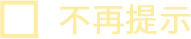

海水淡化工程:运行及维护:operation and maintenance

¥29.4

(2.9折)

?

1星价

¥42.0

2星价¥42.0

定价¥100.0

温馨提示:5折以下图书主要为出版社尾货,大部分为全新(有塑封/无塑封),个别图书品相8-9成新、切口有划线标记、光盘等附件不全详细品相说明>>

暂无评论

图文详情

- ISBN:9787560350561

- 装帧:一般胶版纸

- 册数:暂无

- 重量:暂无

- 开本:23cm

- 页数:307

- 出版时间:2015-06-01

- 条形码:9787560350561 ; 978-7-5603-5056-1

内容简介

水环境联合会和水分重用协会出版物描述了先进的操作、维护和故障排除的方法为反渗透咸水和海水淡化工厂市政摘要给水。所有植物组件详细讨论,从摄入和预处理放电管理。维护工厂设备也提供了实践。实际的例子说明新的技术和实用的实现都包含在这个资源。

目录

Preface

Acknowledgments

Abbreviations

1 I ntroduction

1.1 Reverse Osmosis Fundamentals

1.1.1 Key Components of the Desalination Plant Treatment Process

1.1.2 Key Performance Parameters of RO Systems

1.1.3 Desalination Plant Classification and Configuration

1.1.4 Criteria for Well—Operating Plants

1.2 Source Water Quality Characterization

1.2.1 Minerals

1.2.2 Dissolved Gases

1.2.3 Particulate Foulants and Measurement Methods

1.2.4 Colloidal Foulants

1.2.5 Mineral Membrane—Scaling Compounds

1.2.6 Natural Organic Foulants

1.2.7 Microbiological Foulants and Membrane Biofouling

1.2.8 Pathogens

1.2.9 Oxidants

1.2.10 Compounds That Could Damage RO Membranes

1.2.11 Compounds Impacting Discharge Quality

References

2 Source Water Intakes

2.1 Open Intakes

2.1.1 Inlet Structure and Coarse Screens

2.1.2 Intake Water Conduit

2.1.3 Intake Screens

2.1.4 Intake Pump Station

2.2 Subsurface Intakes

2.2.1 Purpose and Function

2.2.2 Routine Operation

2.2.3 Performance Monitoring

2.2.4 Maintenance

2.2.5 Troubleshooting

References

3 Source Water Pretreatment

3.1 Source Water Chemical Conditioning Systems

3.1.1 Coagulant Feed Systems

3.1.2 Flocculant Feed Systems

3.1.3 Scale Inhibitor Feed Systems

3.1.4 Biocide Feed Systems

3.1.5 Dechlorination Feed Systems

3.1.6 Acid Feed Systems

3.1.7 Sodium Hydroxide Feed Systems

3.1.8 Summary of Typical Operational Problems of Source Water Conditioning and Troubleshooting

3.2 Dissolved Air Flotation Clarifiers

3.2.1 Purpose and Function

3.2.2 Routine Operation

3.2.3 Performance Monitoring

3.2.4 Maintenance

3.2.5 Troubleshooting

3.3 Granular Media Pretreatment Filters

3.3.1 Purpose and Function

3.3.2 Routine Operation

3.3.3 Performance Monitoring

3.3.4 Maintenance

3.3.5 Troubleshooting

3.4 Membrane Pretreatment Filters

3.4.1 Purpose and Function

3.4.2 Routine Operation

3.4.3 Performance Monitoring

3.4.4 Maintenance

3.4.5 Troubleshooting

3.5 Cartridge Filters

3.5.1 Purpose and Function

3.5.2 Routine Operation

3.5.3 Performance Monitoring

3.5.4 Troubleshooting

References

4 Reverse Osmosis System Operation

4.1 Reverse Osmosis Desalination System

4.1.1 Key RO System Components

4.1.2 Purpose and Function

4.2 Routine RO System Operation

4.2.1 Maintaining RO System Fresh Water Production Rate

4.2.2 Maintaining RO System Permeate Quality

4.2.3 Alternative Approaches for RO System Operation

4.2.4 RO System Startup

4.2.5 Key Routine Operational Tasks

4.3 Performance Monitoring

4.3.1 Performance Data Collection

4.3.2 Impacts of Source Water and Operational Parameters on RO System Performance

4.3.3 Performance Data Analysis and Normalization

4.4 RO System Maintenance

4.4.1 RO Membrane Flushing and Preservation

4.4.2 RO Membrane Cleaning

4.4.3 RO Membrane Rotation

4.4.4 RO Membrane Replacement

References

5 Reverse Osmosis System Troubleshooting

5.1 Overview of RO System Performance Challenges

5.2 RO Process Performance Challenges

5.2.1 Permeate Production Below Target Flow Rate

5.2.2 Inadequate Permeate Water Quality

5.2.3 Excessive Membrane Cleaning Frequency and Energy Use

5.3 Diagnostics of RO Membrane System Performance

5.3.1 Diagnostics of RO Membrane Integrity and Fouling Issues

5.3.2 Diagnostics of Membrane Fouling and Scaling Issues

5.3.3 Membrane Autopsy

5.4 Key Equipment Performance Issues and Troubleshooting Solutions

5.4.1 RO High—Pressure Feed Pumps

5.4.2 Energy Recovery Systems

References

6 Post—Treatment

6.1 Introduction

6.2 Lime/Carbon Dioxide Post—Treatment Systems

6.2.1 Purpose and Function

6.2.2 Routine Operation

6.2.3 Performance Monitoring

6.2.4 Maintenance

6.2.5 Troubleshooting

6.3 Calcite Conditioning Systems

6.3.1 Purpose and Function

6.3.2 Routine Operation

6.3.3 Performance Monitoring

6.3.4 Maintenance

6.3.5 Troubleshooting

6.4 Remineralization by Mixing of Desalinated and Source Waters

6.4.1 Purpose and Function

6.4.2 Routine Operation

6.4.3 Performance Monitoring

6.4.4 Maintenance

6.4.5 Troubleshooting

6.5 Disinfection Systems

6.5.1 Purpose and Function

6.5.2 Disinfection Methods

6.5.3 Routine Operation, Performance Monitoring, Maintenance, and Troubleshooting

References

7 Desalination Plant Discharge Management

7.1 Introduction

7.1.1 Concentrate

7.1.2 Backwash Water

7.1.3 Other Nonconcentrate Side Streams

7.2.Concentrate Discharge to Surface Waters

7.2.1 Purpose and Function

7.2.2 Routine Operation

7.2.3 Monitoring of Discharge Water Quantity and Quality

7.2.4 Maintenance and Troubleshooting

7.3 Backwash Settling and Sludge Dewatering Systems

7.3.1 Purpose and Function

7.3.2 Routine Operation

7.3.3 Performance Monitoring

7.3.4 Maintenance

7.3.5 Troubleshooting

References

8 Equipment Maintenance

8.1 Introduction

8.2 Pumps

8.2.1 Purpose and Function

8.2.2 Routine Inspection and Maintenance Considerations

8.2.3 Troubleshooting

8.3 Air Blowers

8.3.1 Purpose and Function

8.3.2 Routine Inspection and Maintenance

8.4 Motors

8.4.1 Purpose and Function

8.4.2 Routine Inspection and Maintenance

8.4.3 Troubleshooting

8.5 Bearings

8.5.1 Purpose and Function

8.5.2 Routine Inspection and Maintenance

8.5.3 Troubleshooting

8.6 Valves

8.6.1 Butterfly Valves

8.6.2 Plug Valves

8.6.3 Ball Valves

8.6.4 Check Valves

8.6.5 Gate Valves

8.6.6 Diaphragm Valves

8.7 Mechanical Seals

8.7.1 Purpose and Functions

8.7.2 Inspection, Maintenance, and Troubleshooting

8.8 Mechanical Drives

8.8.1 Purpose and Function

8.8.2 Inspection, Maintenance, and Troubleshooting

8.9 Chemical Feed Systems

8.9.1 Purpose and Function

8.9.2 Inspection, Maintenance, and Troubleshooting

8.10 Automatic Samplers

8.10.1 Purpose and Function

8.10.2 Inspection, Maintenance, and Troubleshooting

Reference

Glossary

Index

Acknowledgments

Abbreviations

1 I ntroduction

1.1 Reverse Osmosis Fundamentals

1.1.1 Key Components of the Desalination Plant Treatment Process

1.1.2 Key Performance Parameters of RO Systems

1.1.3 Desalination Plant Classification and Configuration

1.1.4 Criteria for Well—Operating Plants

1.2 Source Water Quality Characterization

1.2.1 Minerals

1.2.2 Dissolved Gases

1.2.3 Particulate Foulants and Measurement Methods

1.2.4 Colloidal Foulants

1.2.5 Mineral Membrane—Scaling Compounds

1.2.6 Natural Organic Foulants

1.2.7 Microbiological Foulants and Membrane Biofouling

1.2.8 Pathogens

1.2.9 Oxidants

1.2.10 Compounds That Could Damage RO Membranes

1.2.11 Compounds Impacting Discharge Quality

References

2 Source Water Intakes

2.1 Open Intakes

2.1.1 Inlet Structure and Coarse Screens

2.1.2 Intake Water Conduit

2.1.3 Intake Screens

2.1.4 Intake Pump Station

2.2 Subsurface Intakes

2.2.1 Purpose and Function

2.2.2 Routine Operation

2.2.3 Performance Monitoring

2.2.4 Maintenance

2.2.5 Troubleshooting

References

3 Source Water Pretreatment

3.1 Source Water Chemical Conditioning Systems

3.1.1 Coagulant Feed Systems

3.1.2 Flocculant Feed Systems

3.1.3 Scale Inhibitor Feed Systems

3.1.4 Biocide Feed Systems

3.1.5 Dechlorination Feed Systems

3.1.6 Acid Feed Systems

3.1.7 Sodium Hydroxide Feed Systems

3.1.8 Summary of Typical Operational Problems of Source Water Conditioning and Troubleshooting

3.2 Dissolved Air Flotation Clarifiers

3.2.1 Purpose and Function

3.2.2 Routine Operation

3.2.3 Performance Monitoring

3.2.4 Maintenance

3.2.5 Troubleshooting

3.3 Granular Media Pretreatment Filters

3.3.1 Purpose and Function

3.3.2 Routine Operation

3.3.3 Performance Monitoring

3.3.4 Maintenance

3.3.5 Troubleshooting

3.4 Membrane Pretreatment Filters

3.4.1 Purpose and Function

3.4.2 Routine Operation

3.4.3 Performance Monitoring

3.4.4 Maintenance

3.4.5 Troubleshooting

3.5 Cartridge Filters

3.5.1 Purpose and Function

3.5.2 Routine Operation

3.5.3 Performance Monitoring

3.5.4 Troubleshooting

References

4 Reverse Osmosis System Operation

4.1 Reverse Osmosis Desalination System

4.1.1 Key RO System Components

4.1.2 Purpose and Function

4.2 Routine RO System Operation

4.2.1 Maintaining RO System Fresh Water Production Rate

4.2.2 Maintaining RO System Permeate Quality

4.2.3 Alternative Approaches for RO System Operation

4.2.4 RO System Startup

4.2.5 Key Routine Operational Tasks

4.3 Performance Monitoring

4.3.1 Performance Data Collection

4.3.2 Impacts of Source Water and Operational Parameters on RO System Performance

4.3.3 Performance Data Analysis and Normalization

4.4 RO System Maintenance

4.4.1 RO Membrane Flushing and Preservation

4.4.2 RO Membrane Cleaning

4.4.3 RO Membrane Rotation

4.4.4 RO Membrane Replacement

References

5 Reverse Osmosis System Troubleshooting

5.1 Overview of RO System Performance Challenges

5.2 RO Process Performance Challenges

5.2.1 Permeate Production Below Target Flow Rate

5.2.2 Inadequate Permeate Water Quality

5.2.3 Excessive Membrane Cleaning Frequency and Energy Use

5.3 Diagnostics of RO Membrane System Performance

5.3.1 Diagnostics of RO Membrane Integrity and Fouling Issues

5.3.2 Diagnostics of Membrane Fouling and Scaling Issues

5.3.3 Membrane Autopsy

5.4 Key Equipment Performance Issues and Troubleshooting Solutions

5.4.1 RO High—Pressure Feed Pumps

5.4.2 Energy Recovery Systems

References

6 Post—Treatment

6.1 Introduction

6.2 Lime/Carbon Dioxide Post—Treatment Systems

6.2.1 Purpose and Function

6.2.2 Routine Operation

6.2.3 Performance Monitoring

6.2.4 Maintenance

6.2.5 Troubleshooting

6.3 Calcite Conditioning Systems

6.3.1 Purpose and Function

6.3.2 Routine Operation

6.3.3 Performance Monitoring

6.3.4 Maintenance

6.3.5 Troubleshooting

6.4 Remineralization by Mixing of Desalinated and Source Waters

6.4.1 Purpose and Function

6.4.2 Routine Operation

6.4.3 Performance Monitoring

6.4.4 Maintenance

6.4.5 Troubleshooting

6.5 Disinfection Systems

6.5.1 Purpose and Function

6.5.2 Disinfection Methods

6.5.3 Routine Operation, Performance Monitoring, Maintenance, and Troubleshooting

References

7 Desalination Plant Discharge Management

7.1 Introduction

7.1.1 Concentrate

7.1.2 Backwash Water

7.1.3 Other Nonconcentrate Side Streams

7.2.Concentrate Discharge to Surface Waters

7.2.1 Purpose and Function

7.2.2 Routine Operation

7.2.3 Monitoring of Discharge Water Quantity and Quality

7.2.4 Maintenance and Troubleshooting

7.3 Backwash Settling and Sludge Dewatering Systems

7.3.1 Purpose and Function

7.3.2 Routine Operation

7.3.3 Performance Monitoring

7.3.4 Maintenance

7.3.5 Troubleshooting

References

8 Equipment Maintenance

8.1 Introduction

8.2 Pumps

8.2.1 Purpose and Function

8.2.2 Routine Inspection and Maintenance Considerations

8.2.3 Troubleshooting

8.3 Air Blowers

8.3.1 Purpose and Function

8.3.2 Routine Inspection and Maintenance

8.4 Motors

8.4.1 Purpose and Function

8.4.2 Routine Inspection and Maintenance

8.4.3 Troubleshooting

8.5 Bearings

8.5.1 Purpose and Function

8.5.2 Routine Inspection and Maintenance

8.5.3 Troubleshooting

8.6 Valves

8.6.1 Butterfly Valves

8.6.2 Plug Valves

8.6.3 Ball Valves

8.6.4 Check Valves

8.6.5 Gate Valves

8.6.6 Diaphragm Valves

8.7 Mechanical Seals

8.7.1 Purpose and Functions

8.7.2 Inspection, Maintenance, and Troubleshooting

8.8 Mechanical Drives

8.8.1 Purpose and Function

8.8.2 Inspection, Maintenance, and Troubleshooting

8.9 Chemical Feed Systems

8.9.1 Purpose and Function

8.9.2 Inspection, Maintenance, and Troubleshooting

8.10 Automatic Samplers

8.10.1 Purpose and Function

8.10.2 Inspection, Maintenance, and Troubleshooting

Reference

Glossary

Index

展开全部

本类五星书

本类畅销

-

勒维特之星-大发现系列丛书

¥4.0¥16.0 -

喜马拉雅山珍稀鸟类图鉴

¥27.2¥68.0 -

昆虫的生存之道

¥12.2¥38.0 -

昆虫采集制作及主要目科简易识别手册

¥15.0¥50.0 -

古文诗词中的地球与环境事件

¥8.7¥28.0 -

声音简史

¥21.3¥52.0 -

不匹配的一对:动物王国的性别文化

¥16.7¥42.8 -

物理学之美-插图珍藏版

¥20.7¥69.0 -

现代物理学的概念和理论

¥18.4¥68.0 -

技术史入门

¥14.4¥48.0 -

几何原本

¥35.6¥93.6 -

改变世界的发现

¥15.4¥48.0 -

图说相对论(32开平装)

¥13.8¥46.0 -

数学的魅力;初等数学概念演绎

¥7.7¥22.0 -

星空探奇

¥14.0¥39.0 -

宇宙与人

¥10.5¥35.0 -

数学专题讲座

¥13.3¥29.0 -

袁隆平口述自传

¥19.9¥51.0 -

为了人人晓得相对论

¥3.9¥13.5 -

一代神话:哥本哈根学派

¥8.1¥15.5