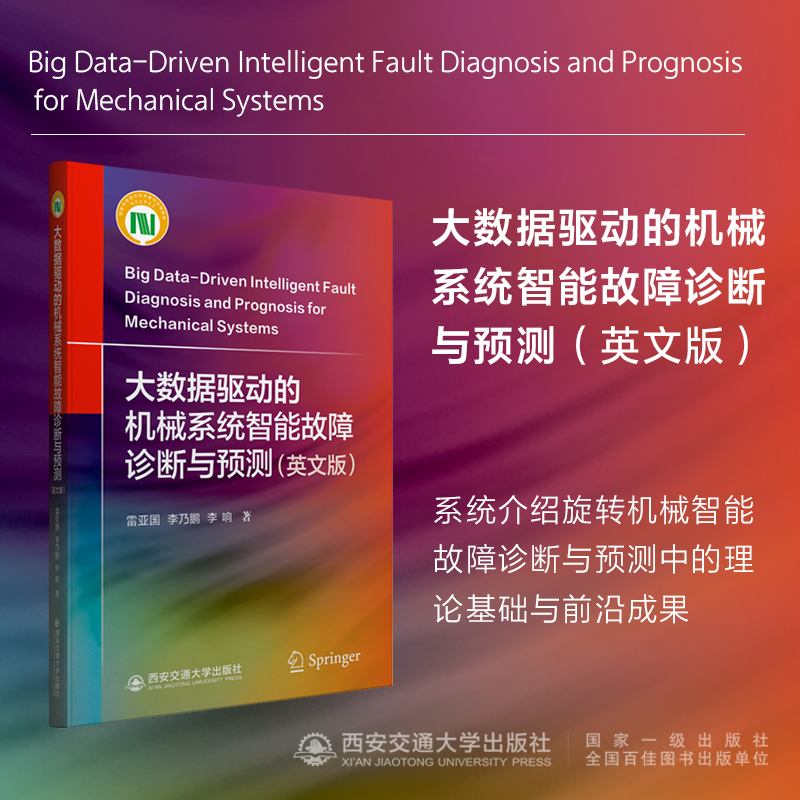

大数据驱动的机械系统智能故障诊断与预测

1星价

¥182.4

(8.0折)

2星价¥182.4

定价¥228.0

暂无评论

图文详情

- ISBN:9787569328028

- 装帧:精装

- 册数:暂无

- 重量:暂无

- 开本:16开

- 页数:293

- 出版时间:2023-01-01

- 条形码:9787569328028 ; 978-7-5693-2802-8

内容简介

本书抓住工业化与信息化深度融合的时代契机,面向新一代人工智能技术,立足于我国机械装备智能诊断与预测迫切工程需求应运而生。围绕大数据驱动的机械装备智能诊断与预测,详细介绍了故障深度智能诊断、故障智能迁移诊断、数模联动剩余寿命预测等前沿方法与技术。聚焦大数据驱动的机械系统智能诊断和预测方法,解决了当前PHM领域的关键挑战,是面向大数据智能诊断与预测领域的系统性、综合性书籍; 介绍了智能故障诊断和预测的基础理论和前沿研究,包括基于深度迁移学习的智能故障诊断、大数据驱动的寿命预测、数模联动健康状态预测等; 附带大量实验验证及工程案例,向读者形象地展示方法实施与技术应用过程,为相关领域课程教学、科学研究和工程实际应用提供丰富素材与详细指导。

目录

1 Introduction and Background

1.1 Introduction

1.1.1 AI Technologies for Data Processing

1.1.2 Big Data-Driven Intelligent Predictive Maintenance

1.1.3 Big Data Analytics Platform Practices

1.2 Overview of Big Data-Driven PHM

1.2.1 Data Acquisition

1.2.2 Data Processing

1.2.3 Diagnosis

1.2.4 Prognosis

1.2.5 Maintenance

1.3 Preface to Book Chapters

References

2 Conventional Intelligent Fault Diagnosis

2.1 Introduction

2.2 Typical Neural Network-Based Methods

2.2.1 Introduction to Neural Networks

2.2.2 Intelligent Diagnosis Using Radial Basis Function Network

2.2.3 Intelligent Diagnosis Using Wavelet Neural Network

2.2.4 Epilog

2.3 Statistical Learning-Based Methods

2.3.1 Introduction to Statistical Learning

2.3.2 Intelligent Diagnosis Using Support Vector Machine

2.3.3 Intelligent Diagnosis Using Relevant Vector Machine

2.3.4 Epilog

2.4 Conclusions

References

3 Hybrid Intelligent Fault Diagnosis

3.1 Introduction

3.2 Multiple WKNN Fault Diagnosis

3.2.1 Motivation .

3.2.2 Diagnosis Model Based on Combination of Multiple WKNN

3.2.3 Intelligent Diagnosis Case Study of Rolling Element Bearings

3.2.4 Epilog

3.3 Multiple ANFIS Hybrid Intelligent Fault Diagnosis

3.3.1 Motivation

3.3.2 Multiple ANFIS Combination with GA

3.3.3 Fault Diagnosis Method Based on Multiple ANFIS Combination

3.3.4 Intelligent Diagnosis Case of Rolling Element Bearings

3.3.5 Epilog

3.4 A Multidimensional Hybrid Intelligent Method

3.4.1 Motivation

3.4.2 Multiple Classifier Combination

3.4.3 Diagnosis Method Based on Multiple Classifier Combination

3.4.4 Intelligent Diagnosis Case of Gearboxes

3.4.5 Epilog

3.5 Conclusions

References

4 Deep Transfer Learning-Based Intelligent Fault Diagnosis

4.1 Introduction

4.2 Deep Belief Network for Few-Shot Fault Diagnosis

4.2.1 Motivation

4.2.2 Deep Belief Network-Based Diagnosis Model with Continual Learning

4.2.3 Few-Shot Fault Diagnosis Case of Industrial Robots

4.2.4 Epilog

4.3 Multi-Layer Adaptation Network for Fault Diagnosis with Unlabeled Data

4.3.1 Motivation

4.3.2 Multi-Layer Adaptation Network-Based Diagnosis Model

4.3.3 Fault Diagnosis Case of Locomotive Bearings with Unlabeled Data

4.3.4 Epilog

4.4 Deep Partial Adaptation Network for Domain-Asymmetric Fault Diagnosis

4.4.1 Motivation

4.4.2 Deep Partial Transfer Learning Net-Based Diagnosis Model

4.4.3 Partial Transfer Diagnosis of Gearboxes with Domain Asymmetry

4.4.4 Epilog

4.5 Instance-Level Weighted Adversarial Learning for Open-Set Fault Diagnosis

4.5.1 Motivation

4.5.2 Instance-Level Weighted Adversarial Learning-Based Diagnosis Model

4.5.3 Fault Diagnosis Case of Rolling Bearing Datasets

4.5.4 Epilog

4.6 Conclusions

References

5 Data-Driven RUL Prediction

5.1 Introduction

5.2 Deep Separable Convolutional Neural Network-Based RUL Prediction

5.2.1 Motivation

5.2.2 Deep Separable Convolutional Network

5.2.3 Architecture of DSCN

5.2.4 RUL Prediction Case of Accelerated Degradation Experiments of Rolling Element Bearings

5.2.5 Epilog

5.3 Recurrent Convolutional Neural Network-Based RUL Prediction

5.3.1 Motivation

5.3.2 Recurrent Convolutional Neural Network

5.3.3 Architecture of RCNN

5.3.4 RUL Prediction Case Study of FEMTO-ST Accelerated Degradation Tests of Rolling Element Bearings

5.3.5 Epilog

5.4 Multi-scale Convolutional Attention Network-Based RUL Prediction

5.4.1 Motivation

5.4.2 Multi-scale Convolutional Attention Network

5.4.3 Architecture of MSCAN

5.4.4 RUL Prediction Case of a Life Testing of Milling Cutters

5.4.5 Epilog

5.5 Conclusions

References

6 Data-Model Fusion RUL Prediction

6.1 Introduction

6.2 RUL Prediction with Random Fluctuation Variability

6.2.1 Motivation

6.2.2 RUL Prediction Considering Random Fluctuation Variability

6.2.3 RUL Prediction Case of FEMTO-ST Accelerated Degradation Tests of Rolling Element Bearings

6.2.4 Epilog

6.3 RUL Prediction with Unit-to-Unit Variability

6.3.1 Motivation

6.3.2 RUL Prediction Model Considering Unit-to-Unit Variability

6.3.3 RUL Prediction Case of Turbofan Engine Degradation Dataset

6.3.4 Epilog

6.4 RUL Prediction with Time-Varying Operational Conditions

6.4.1 Motivation

6.4.2 RUL Prediction Model Considering Time-Varying Operational Conditions

6.4.3 RUL Prediction Case of Accelerated Degradation Experiments of Thrusting Bearings

6.4.4 Epilog

6.5 RUL Prediction with Dependent Competing Failure Processes

6.5.1 Motivation

6.5.2 RUL Prediction Model Considering Dependent Competing Failure Processes

6.5.3 RUL Prediction Case of Accelerated Degradation Experiments of Rolling Element Bearings

6.5.4 Epilog

6.6 Conclusions

References

Glossary

展开全部

作者简介

雷亚国(Yaguo Lei),博士、教授、博士生导师、德国洪堡学者。分别于2002年和2007年获西安交通大学机械工程专业学士学位和工学博士学位。

本类五星书

本类畅销

-

落洼物语

¥9.0¥28.0 -

北大人文课(平装)

¥16.7¥45.0 -

(平装)北大心理课

¥14.4¥45.0 -

原野之窗生物多样性教育课程

¥43.1¥88.0 -

中医基础理论

¥50.7¥59.0 -

毛泽东思想和中国特色社会主义理论体系概论(2021年版)

¥10.8¥25.0 -

北大哲学课(平装)

¥16.7¥45.0 -

经济法案例评析

¥29.3¥39.0 -

中国古代文学史-(上)

¥18.8¥43.7 -

婴幼儿护理师

¥32.3¥38.0 -

综合能源服务导论

¥36.8¥49.0 -

初等几何研究

¥3.4¥8.7 -

政治经济学概论(第六版)(高等学校经济管理类核心课程教材)

¥44.2¥52.0 -

常微分方程 (第五版)

¥24.5¥34.0 -

马克思主义基本原理2021年版

¥11.3¥23.0 -

大学物理学(第4版)电磁学、光学、量子物理

¥56.7¥81.0 -

∈网络传播概论(第四版)

¥41.9¥59.8 -

(本科教材)西方哲学简史

¥40.6¥58.0 -

VB语言程序设计

¥27.9¥39.8 -

古代汉语(第四册)

¥15.1¥35.0