暂无评论

图文详情

- ISBN:9787030435927

- 装帧:一般胶版纸

- 册数:暂无

- 重量:暂无

- 开本:大16开

- 页数:362

- 出版时间:2015-04-01

- 条形码:9787030435927 ; 978-7-03-043592-7

本书特色

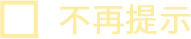

中国大陆科学钻探工程是我国“九五”期间立项的国家重大科学工程项目之一,同时也是国际大陆科学钻探计划(icdp)项目,被称为中国科钻一井(ccsd-1)。《中国大陆科学钻探工程(英文版)》利用钻探新技术在坚硬结晶岩地层实施一口5000米深孔,全孔连续采取岩心,利用岩心及原位观测数据,进行多学科研究,揭示超高压变质带的形成与折返机理,并利用5000米超深钻孔建立长期观测站。

内容简介

中国大陆科学钻探工程是我国“九五”期间立项的国家重大科学工程项目之一,同时也是国际大陆科学钻探计划(ICDP)项目,被称为中国科钻一井(CCSD-1)。《中国大陆科学钻探工程(英文版)》利用钻探新技术在坚硬结晶岩地层实施一口5000米深孔,全孔连续采取岩心,利用岩心及原位观测数据,进行多学科研究,揭示超高压变质带的形成与折返机理,并利用5000米超深钻孔建立长期观测站。

目录

Contents1 Background 11.1 Scientific DrillingA New Field of Earth Science 11.2 A Brief Introduction of China Continental Scientific Drilling Project 11.3 Site Selection and Scientific and Technological Objectives 21.4 Developing History of CCSD Engineering 31.4.1 Early Stage of Understanding (Before 1991) 31.4.2 Project Argumentation and Demonstration Stage(1991September 1999) 41.4.3 Project Preparation Stage (September 1999June 2001) 51.4.4 Project Implementation Stage (June 2001April 2005) 61.5 Technical Preparation 71.5.1 Technical Training 81.5.2 Prepilot Hole Construction 91.5.3 Preresearch on Key Technologies 102 Drilling Engineering Design 152.1 Assignment of Drilling 152.2 Basic Situation of the Well Site 152.2.1 Forecast of Lithological Profile of the Formation Encountered 162.3 Lithologic Characteristic of the Rock Formations to be Encountered by Drilling 172.4 Drilling Technical Program182.4.1 Combined Drilling Techniques 182.4.2 Flexible Double Hole Program 192.4.3 Feel Ahead Open Hole Drilling Techniques 192.5 Borehole Structure and Casing Program 202.5.1 Designed Borehole Structure and Casing Program for the Pilot Hole 202.5.2 Designed Borehole Structure and Casing Program for the Main Hole 202.6 Drilling Equipment Program 202.6.1 Main Drilling Equipment 202.6.2 Equipment and Instruments Should Be Added 222.7 Drilling String Program 222.8 Core Drilling Program 232.8.1 Wireline Core Drilling 232.8.2 Hydrohammer Wireline Core Drilling Tool 252.8.3 PDM Wireline Core Drilling Tool 252.8.4 Turbomotor Wireline Core Drilling Tool 252.8.5 Conventional Core Drilling Tool262.8.6 Hydrohammer Core Drilling Tool 262.8.7 PDM Core Drilling Tool 282.8.8 Design Program of Diamond Core Drill Bit and Reaming Shell 282.9 Hole Deviation Control Program 292.9.1 Deviation Prevention for Cored Hole Section and Monitor Measures 312.9.2 Deviation Control Measure for Cored Hole Section 312.9.3 Deviation Control Measure for the Upper Section of the Main Hole Where Noncore Drilling Was Conducted 312.10 Noncore Drilling and Reaming Drilling Program 312.10.1 Design of Drilling Tool Assembly For Noncore Drilling 312.10.2 Design of Drilling Tool Assembly for Reaming Drilling 322.10.3 Selection of Noncore Drill Bit 322.10.4 Design of Reaming Drill Bit 332.11 Drilling Fluid Technique and Solid Control Program 332.11.1 The Main Technical Problems Should Be Considered 332.11.2 Design of Drilling Fluid Type 342.11.3 Solid Control 342.12 Well Cementation and Completion Program 342.12.1 Well Cementation Program 342.12.2 Principle in Design of Casing String Strength 352.12.3 Well Completion Operation 362.13 Design of Moving Casing 362.13.1 Necessity of Adopting Moving Casing Design 362.13.2 Fixing of Moving Casing372.13.3 Safety Management of Moving Casing 372.14 Time and Cost Estimation 382.14.1 Designed Construction Progress 382.14.2 Budgetary Estimation of Cost 382.15 Change and Modification of Design 383 Well Site and Drilling Equipment 473.1 Well Site 473.2 Drilling Equipment 493.2.1 ZJ70D Drill Rig503.2.2 Drill Rig Reconstruction 533.2.3 The Power System 563.2.4 Corollary Equipment 573.2.5 Application Evaluation on ZJ70D Drill Rig 604 Construction Situation 634.1 Basic Situation of the Construction of CCSD1 Well 634.1.1 The Basic Data 634.1.2 Drill Hole Trajectory 674.1.3 Well Temperature Curve 684.2 Simple Situation of the Construction at Different Periods 694.2.1 Hole Opening and Noncore Drilling (the First Opening) 694.2.2 Pilot Hole (Section CCSDPH) Core Drilling(the Second Opening) 714.2.3 The First Expanding Drilling of the Main Hole(Hole Section CCSDMHIK) 744.2.4 The First Core Drilling of the Main Hole (Hole Section CCSDMH, the Third Hole Opening) 774.2.5 The First Sidetracking (Deviation Correction) Drilling of the Main Hole 824.2.6 The Second Core Drilling of the Main Hole(Hole Section CCSDMHIC) 894.2.7 The Second Expanding Drilling of the Main Hole(Hole Section CCSDMH2K) 914.2.8 The Second Sidetracking (Obstacle Avoidance) Drilling and Running Casing and Well Cementation in the Main Hole 974.2.9 The Third Core Drilling of the Main Hole(Section CCSDMH2C. the Fourth Opening) 994.2.10 Testing Drilling Tools 1024.2.11 Well Completion 1055 Hard Rock Deep Well Core Drilling Techniques 1075.1 Current Status of Core Drilling Techniques 1075.2 Experiment on Core Drilling Methods for CCSD1 Well 1085.2.1 Rotary Table Drive Double Tube Core Drilling 1085.2.2 Rotary Table Hydrohammer Drive Double Tube Core Drilling 1095.2.3 Top Drive Double Tube Core Drilling 1095.2.4 Top Drive Wireline Core Drilling 1105.2.5 Top Drive Hydrohammer Wireline Core Drilling 1115.2.6 PDM Drive Single Tube Core Drilling 1115.2.7 PDM Drive Double Tube Core Drilling 1135.2.8 PDM Drive Wireline Core Drilling 1145.2.9 PDM Hydrohammer Drive Double Tube Core Drilling 1165.2.10 PDM Hydrohammer Drive Wireline Core Drilling 1165.2.11 Summary of the Tests for Core Drilling Methods 1185.3 Down Hole Power Percussive Rotary Core Drilling System 1195.3.1 Constituent of the System 1195.3.2 Technical Data of the System 1215.3.3 Down Hole Rotary Drive Drilling ToolPDM 1275.3.4 Down Hole Percussive Drilling ToolHydrohammer 1285.3.5 Core Drilling Tool 1555.3.6 Core Drilling Technologies 1665.3.7 The Application Results of Hard Rock Deep Well Core Drilling Techniques 1726 Diamond Core Drill Bit 1836.1 The Physical and Mechanical Properties of the Rocks to Be Drilled 1836.1.1 The Properties of the Rocks to Be Drilled 1836.1.2 The Physical and Mechanical Properties of the Rocks 1836.2 Selection of Diamond Core Drill Bit Types 1856.2.1 Core Drilling Technologies 1856.2.2 Types of Diamond Core Drill Bits 1866.3 Design and Manufacture of Impregnated Diamond Core Drill Bits 1876.3.1 Segment Inserted Drill Bit by Twice Forming 1876.3.2 Sintered Diamond Drill Bit 1896.3.3 Electroplated Diamond Drill Bit by Twice Forming 1906.4 Application of Diamond Core Drill Bits 1916.4.1 Brief Introduction 1916.4.2 Application Results of Three Main Core Drill Bits 2006.4.3 Application Results of Other Type Core Drill Bits 2057 Reaming Drilling Techniques of Hard Crystalline Rock 2117.1 Development of Pilot Reaming Bits 2117.1.1 K2157/311.1 Type Reaming Bit 2137.1.2 KHAT 157/311.1 Reaming Bit 2157.1.3 Development and Improvement of K2157/244.5 Reaming Bit 2167.2 Design of Drilling Tool 2187.2.1 Strength Check of Drilling String 2187.2.2 Selection of Drilling Tools 2197.2.3 Design of Drilling Tool Assembly 2227.3 0ptimization of Drilling Parameters 2247.3.1 WOB 2247.3.2 Rotary Speed 2247.3.3 Pump Displacement 2267.4 Effect of Reaming Drilling 2267.4.1 General Drilling Conditions 2267.4.2 Application of Pilot Reaming Bits 2288 WellDeviation Control Techniques for Strong Dipping Strata 2338.1 Summary 2338.1.1 The Formation Conditions 2338.1.2 The Well Deviation Control Technology 2358.1.3 The Basic Conditions of Well Deviation Control in CCSD1 Well 2368.2 Deviation Prevention Drilling Technology 2368.2.1 The Well Deviation Control in Core Drilling 2378.2.2 Well Deviation Control in Noncore Drilling and Reaming Drilling 2428.3 Drilling Techniques for Deviation Correction 2448.3.1 SideTracking DeviationCorrection Techniques 2458.3.2 Situation on SideTracking Drilling for DeviationCorrection 2478.3.3 Deviaton Correction at the Well Bottom of MHIC Well Section 2578.4 SideTracking Drilling for Bypassing Obstacles 2608.4.1 Selection of SideTracking Drilling Tool 2608.4.2 Drilling Conditions of SideTracking Drilling to Bypass Obstacles 2608.5 Development of PDM Drive Continuous Deflector 2658.5.1 Working Principle of the Drilling Tool 2658.5.2 Practical Drilling Test at Drill Site 2668.5.3 Test Result Commentary 2688.6 The Analysis on Well Deviation Control Effect 2729 Drilling Fluids and Solids Control Technology 2739.1 Requirements of Scientific Drilling for Drilling Fluid 2739.1.1 Strata Encountered and Requirements of Well Structure 2739.1.2 Requirements of Core Drilling2749.1.3 Requirements of Noncore Drilling and Expanding Drilling 2759.1.4 Requirements of Borehole Log 2759.1.5 Requirements of Environmental Protection 2759.1.6 Requirements of Drilling Fluid Design 2769.2 Drilling Fluid System2769.2.1 Selection of Drilling Fluid System 2779.2.2 LBMSD Composite Drilling Fluid Material 2779.2.3 Drilling Fluid Mechanism and Composition of LPA Polymer 2779.2.4 Manufacture Technology of LBMSD 2809.2.5 Evaluation Procedure of Drilling Fluid 2819.2.6 Performance of LBMSD Drilling Fluid System 2819.3 Drilling Fluid for Core Drilling 2859.3.1 Properties 2859.3.2 Circulating Pressure Drop 2889.3.3 Lubrication Effect of Drilling Fluid 2929.4 Solid Control Technique of Drilling Fluid 2939.4.1 Cuttings Size Analysis 2949.4.2 Requirement of Solids Control Equipment to Drilling Fluid 2959.4.3 Analysis of Solids Control Effect 2959.5 Site Application of Drilling Fluid 2979.5.1 Application of Drilling Fluid in Noncore Drilling in the First Opening (Spuddingin) 2979.5.2 Application of Drilling Fluid in Pilot Hole Core Drilling 2979.5.3 Application of Drilling Fluid in the First Expanding Drilling in the Main Hole 2989.5.4 Application of Drilling Fluid in the First Core Drilling in the Main Hole 2989.5.5 Application of Drilling Fluid in the First Sidetrack Straightening Drilling in the Main Hole 2999.5.6 Application of Drilling Fluid in the Second Core Drilling in the Main Hole2999.5.7 Application of Drilling Fluid in the Second Expanding Drilling in the Main Hole3009.5.8 Application of Drilling Fluid in the Second Sidetrack DrillingAround in the Main Hole 3019.5.9 Application of Drilling Fluid in the Third Core Drilling in the Main Hole 3019.5.10 Application Characteristics of LBM Drilling Fluid 30210 Casing and Well Cementation 30310.1 Borehole Structure and Casing Program 30310.1.1 Borehole Structure and Casing Program for the Pilot Hole 30310.1.2 Borehole Structure and Casing Program for the Main Hole 30310.1.3 Casing Design 30310.2 Well Head Assembly 30610.2.1 Well Head Assembly for the First Opening (Spudin) 30610.2.2 Well Head Assembly for the Second Opening (Spudin) 30710.2.3 Well Head Assembly for the Third and the Fourth Opening (Spudin) 30810.2.4 Well Head Assembly for Well Completion 30810.3 Casing Running and Well Cementing Operation 30810.3.1 508.0 mm Well Head Conductor 30810.3.2 339.7 mm Surface Casing 30910.3.3 273.0 mm Intermediate Casing 31110.3.4 193.7 mm Intermediate Casing 31710.3.5 127.0 mm Tail Pipe 32010.4 Moving Casing Techniques 32210.4.1 0verall Programme 32310.4.2 Design of Fixing Moving Casing 32310.4.3 Moving Casing Strength Check 32510.4.4 Design of Casing Shoe and Retaining Sub 32510.4.5 Design of Thread Backoff Proof for Moving Casing 32710.4.6 Design of Centralizer 32710.4.7 0perating Technology of Moving Casing 32910.4.8 Application of Moving Casing Techniques 32911 Drilling Data Acquisition 33311.1 General Situation 33311.2 Analysis of Data Acquisition and Processing Requirements 33611.2.1 Data Acquisition System Requirements 33611.2.2 Data Processing System Requirements 33611.3 Drilling Data Acquisition System 33711.3.1 Surface Drilling Data Acquisition System 33811.3.2 DownHole Drilling Data Acquisition System 34111.4 Drilling Data Processing System 34311.4.1 Single Parameter Monitoring34311.4.2 Comprehensive Monitoring 34411.4.3 Case History 34512 Technical Economical Analysis 34912.1 Construction Time and Cost Analysis34912.1.1 Construction Time Analysis 34912.1.2 Construction Cost Analysis 34912.2 Economic Evaluation of Core Drilling Techniques 35212.2.1 Evaluation Method 35212.2.2 Index System of Technical Economic Evaluation for Core Drilling Construction35312.2.3 Calculation of Drilling Construction Time and Cost 35312.2.4 Technical Economical Indexes of Different Core Drilling Methods 35512.2.5 Economic Evaluation 35512.2.6 Technical Risk Evaluation 35512.2.7 Comprehensive Evaluation 358References361

展开全部

本类五星书

本类畅销

-

铁道之旅:19世纪空间与时间的工业化

¥20.7¥59.0 -

金属材料及热处理

¥46.8¥72.0 -

中国传统民俗文化:建筑系列:中国古代桥梁

¥20.9¥58.0 -

嗨印刷工艺(Vol1烫印)(精)

¥147.4¥268.0 -

西门子S7-1200 PLC项目化教程

¥39.4¥54.0 -

装配化工字组合梁设计

¥88.0¥160.0 -

高聚物粘结及其性能

¥34.8¥120.0 -

汽车风云人物

¥13.5¥50.0 -

品牌鞋靴产品策划-从创意到产品

¥26.5¥42.0 -

城市桥梁工程施工与质量验收手册-(含光盘)

¥61.6¥78.0 -

城镇道路工程施工与质量验收规范实施手册

¥16.4¥39.0 -

长江航运文化

¥21.2¥46.0 -

航空发动机限寿件概率损伤容限评估概述

¥67.8¥88.0 -

天才武器

¥42.0¥60.0 -

中国再制造进展

¥88.5¥118.0 -

中国烹饪工艺学粤菜教程

¥48.4¥59.8 -

蓝色水星球 重新思考我们在宇宙中的家园

¥60.7¥88.0 -

面对盖娅:新气候制度八讲

¥69.0¥92.0 -

机械制图

¥37.4¥68.0 -

服饰造型讲座:4:外套·背心

¥37.1¥58.0