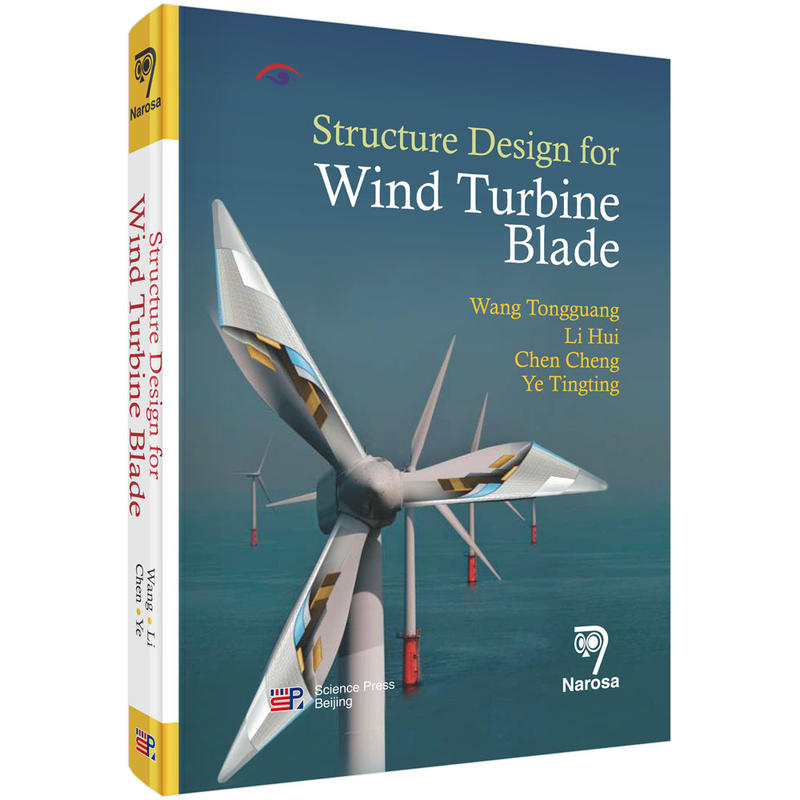

- ISBN:9787030593047

- 装帧:一般胶版纸

- 册数:暂无

- 重量:暂无

- 开本:B5

- 页数:504

- 出版时间:2018-09-01

- 条形码:9787030593047 ; 978-7-03-059304-7

本书特色

本书总结了作者关于风力机叶片结构设计方面的经验,系统地阐述了复合材料型风力机叶片结构应用的设计方法和技术方案,包括风力机叶片复合材料应用、构件、设计、方法、基础校核及高级校核;重点介绍了风力机叶片结构设计校核的方方面面,涉及基础理论、设计方法、结构校核、全尺寸测试;并结合风力机国际标准和规范给出大量设计实例。

内容简介

本书共分为5篇,21章节。篇为本书~3章,称为基础篇。介绍了结构工程师所需要的一些叶片结构背景信息,以便于灵活学习及应用理论基础,同时指定叶片设计基本准则和复合材料基础;第二篇为本书第4~6章,称为设计篇,介绍了叶片结构件和功能件的构型设计和详细尺寸设计;第三篇为本书第7~11章,称为方法篇,包括叶片结构校核综述及方法,结合风力机叶片的靠前标准阐述叶片结构校核的要求与设计准则,对应于工字梁、薄壁杆件理论和有限元理论,分别介绍一维、二维和三维叶片结构分析方法;第四篇为本书2~16章,称为构件篇,介绍叶片结构的基本校核内容及叶片中的复合材料构件层合结构、夹芯结构、胶接连接和螺栓连接等结构形式的分析方法;第五篇为7~21章,称为提高篇,介绍叶片校核的不错专题部分,包括疲劳分析、抗冲击分析、断裂力学的层间分析与可靠性分析,介绍了很好规结构校核方面的分析方法;在很后一章介绍了本书中未涵盖的内容,重点分析了未来叶片的发展趋势。

目录

作者简介

王同光,南京航空航天大学教授、博导,先后两次主持国家“973”项目并担任首席科学家。现任江苏省风力机设计高技术研究重点实验室主任,江苏省“风能和太阳能发电技术与工程”优势学科带头人。1995-1996年由“中英友好奖学金”资助在英国格拉斯哥大学做访问学者。1996-1999年由英国政府ORS奖学金资助在格拉斯哥大学攻读博士学位。1999年11月-2001年8月在格拉斯哥大学从事由英国EPSRC资助的博士后研究。主持和承担了国家“973”计划、“863”计划、科技支撑计划、欧盟第七框架计划等多项研究。发表论文百余篇,其中被SCI和EI等收录的论文50余篇。

-

铁道之旅:19世纪空间与时间的工业化

¥20.7¥59.0 -

金属材料及热处理

¥46.1¥72.0 -

实用电气计算

¥64.2¥88.0 -

中国传统民俗文化:建筑系列:中国古代桥梁

¥20.9¥58.0 -

嗨印刷工艺(Vol1烫印)(精)

¥147.4¥268.0 -

西门子S7-1200 PLC项目化教程

¥39.4¥54.0 -

变频器维修手册

¥69.3¥99.0 -

装配化工字组合梁设计

¥88.0¥160.0 -

气动系统装调与PLC控制

¥29.1¥39.8 -

高聚物粘结及其性能

¥34.8¥120.0 -

液压控制系统

¥12.7¥31.0 -

汽车风云人物

¥13.5¥50.0 -

品牌鞋靴产品策划-从创意到产品

¥26.5¥42.0 -

城市桥梁工程施工与质量验收手册-(含光盘)

¥61.6¥78.0 -

城镇道路工程施工与质量验收规范实施手册

¥16.4¥39.0 -

航空发动机限寿件概率损伤容限评估概述

¥67.8¥88.0 -

天才武器

¥42.0¥60.0 -

中国再制造进展

¥88.5¥118.0 -

中国烹饪工艺学粤菜教程

¥48.4¥59.8 -

蓝色水星球 重新思考我们在宇宙中的家园

¥60.7¥88.0