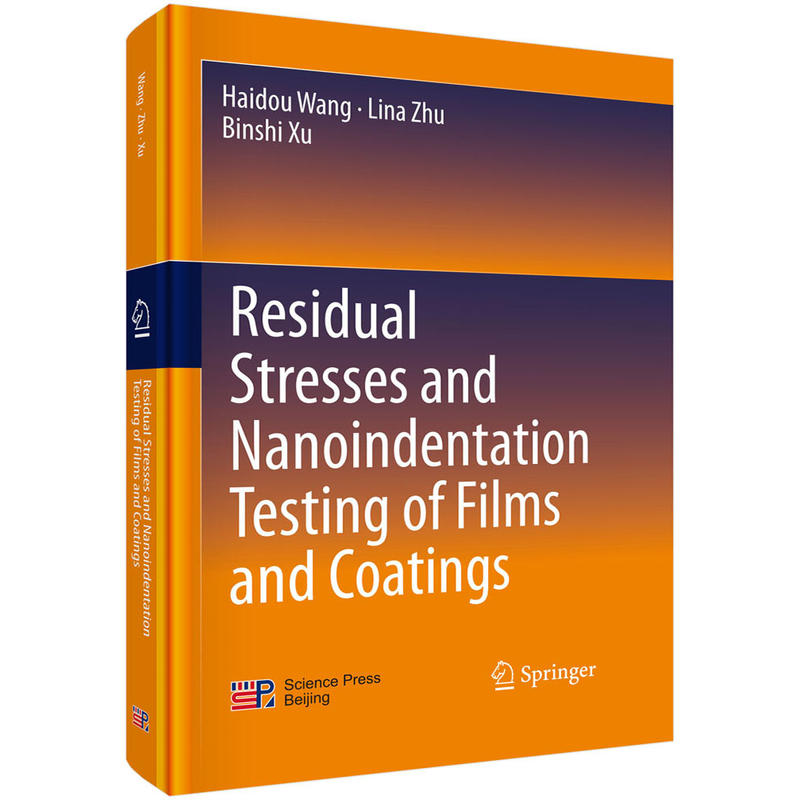

涂层薄膜应力及其纳米压痕检测(英文)

温馨提示:5折以下图书主要为出版社尾货,大部分为全新(有塑封/无塑封),个别图书品相8-9成新、切口有划线标记、光盘等附件不全详细品相说明>>

- ISBN:9787030567314

- 装帧:一般轻型纸

- 册数:暂无

- 重量:暂无

- 开本:B5

- 页数:216

- 出版时间:2018-06-01

- 条形码:9787030567314 ; 978-7-03-056731-4

内容简介

作者编著此书,拟向广大读者介绍优选的纳米压痕技术测量残余应力的基本知识,期望让更多领域的专家与工程技术人员在机械设计、加工制造、维修与再制造中,了解这种测量技术的特点和效果,能合理地进行选用和运用,以求更好地指导生产实践,获得很大的社会与经济效益。本书共分五章,简单介绍了残余应力的形成机理及其对表面性能的影响,系统归纳了传统的残余应力测量技术的原理及缺陷。本书重点介绍了优选的纳米压痕测量技术,深入阐述了不同计算模型的测量原理、适用范围及缺陷,并系统总结了不同模型在残余应力测量中的实际应用。所取材料主要是来自作者近年来的很新研究成果以及该领域同行学者的重要研究内容。

目录

-

黑科技驱动世界的100项技术

¥24.4¥69.8 -

铁道之旅:19世纪空间与时间的工业化

¥20.7¥59.0 -

船舶综合驾驶台通信与导航系统:::

¥41.8¥58.0 -

博识百科系列--汽车摩托车大百科

¥96.6¥138.0 -

实用精细化学品丛书--陶瓷添加剂:配方·性能·应用(第二版)

¥51.8¥69.0 -

西门子S7-1200 PLC项目化教程

¥39.4¥54.0 -

选矿手册。第1卷

¥14.3¥42.0 -

欧亚草原古代治金

¥76.4¥98.0 -

国家电网有限公司安全生产事故事件分析报告汇编(2010-2021年)

¥126.4¥160.0 -

工业聚乙烯导论

¥73.5¥98.0 -

煤矿工人情景意识的fnlrs脑功能连接特征与分类识别研究

¥49.3¥88.0 -

水利水电施工 2022年第6辑

¥17.6¥36.0 -

水利水电施工 2024年第1册

¥17.6¥36.0 -

公路隧道工程施工安全风险评估方法及典型案例分析

¥49.5¥90.0 -

欧亚大陆北部的树皮船与兽皮船

¥132.3¥189.0 -

(教材)产业用纺织品实验教程

¥38.3¥58.0 -

中国船闸文明演变进化史研究

¥49.0¥68.0 -

多媒体多模态融合的情感分析网络

¥17.4¥29.0 -

从模仿到创新:苏联液体弹道火箭技术的发展1944-1951

¥55.4¥88.0 -

水污染治理技术

¥29.0¥46.0