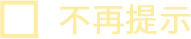

- ISBN:9787122455598

- 装帧:平装

- 册数:暂无

- 重量:暂无

- 开本:24cm

- 页数:270页

- 出版时间:2024-06-01

- 条形码:9787122455598 ; 978-7-122-45559-8

本书特色

《Coal Preparation(选煤工程)》内容是Felicia F. Peng教授1997年至2018年在西弗吉尼亚大学讲授的煤炭洗选课程教学成果的总结,全书为英文版,共十四章,以下为中文内容说明:本书全面阐述了煤炭的环境影响(包括全球变暖)、煤炭的应用、煤炭的赋存和组成及其对洗选工艺的影响等内容。书中详细介绍了各种洗煤工艺及作业单元,包括破碎、筛分、分级、重选、浮选、脱水、干燥等工艺,几乎涵盖了煤炭被开采出地表后所经历的全部处理作业。 为了更好地方便教与学,书中第14章列出了7个家庭作业、5个考试和5个实验,对实验目的、安全设备、实验流程、数据分析方法、结果呈现和报告格式给出了非常详细的说明。可供选煤工业相关生产、技术人员、研发人员和管理人员,选煤专业相关师生学习。

内容简介

本书从煤炭的环境影响(包括全球变暖),煤炭的应用、煤炭的赋存和组成及其对洗选工艺的影响等多个方面进行了阐述。书中详细介绍了各种洗煤工艺及作业单元,包括破碎、筛分、分级、重选、浮选、脱水、干燥等工艺,几乎涵盖了煤炭被开采出地表后所经历的全部处理作业。为了更好地达到教学目的,在第14章列出了7个家庭作业、5个考试和5个实验,对实验目的、安全设备、实验流程、数据分析方法结果呈现和报告格式给出了非常详细的说明。本书可供选煤工业相关生产、技术人员、研发人员和管理人员,以及选煤专业相关师生学习。

目录

1.1 Coal Preparation is a Subsystem of Mining Operations 002

1.2 Objectives of Coal Cleaning 002

1.3 Coal Cleaning Processes 003

1.4 Coal Utilization 004

1.5 Environmental Considerations 005

1.5.1 Clean Air Act of 1990 005

1.5.2 Carbon Dioxide Emission 006

1.6 Transportation Modes of Coal 009

1.6.1 Coal Distribution Methods 009

1.6.2 River Barge Transportation Systems 011 2 COAL 013

2.1 Formation of Coal 014

2.2 Representative Structure of Chemical Groups in Bituminous Coal 015

2.3 Parr Formula and Classification of Coal by Rank 016

2.4 Coal Resources in the United States and West Virginia 020

2.4.1 Coal Resources Distribution in the United States 020

2.4.2 Coal Resources and Coal Seams in West Virginia 021 3 COAL CHARACTERIZATION 025

3.1 Coal Sample Preparation, Analyses, and Specifications 026

3.2 Qualities of Steam and Metallurgical Coals 028

3.3 Characterization of Coal for Combustion 031

3.3.1 Proximate and Ultimate Analyses 032

3.3.2 Sulfur Forms and Analyses (ASTM D3177—89, ASTM D2492—90) 033

3.3.3 Calorific Value of Coal - Adiabatic Bomb Calorimeter (ASTM D5865—99a) 035

3.4 Hardgrove Grindability Index (HGI) 035

3.5 Mineral Matter in Coal and Ash Analysis 037

3.5.1 Mineral Matter in Coal 037

3.5.2 Fusibility of Coal Ash 039

3.6 Coal Ash Characterization 040

3.6.1 Coal Ash Slagging Potential and Deposition Indicators 041

3.6.2 Slagging Potential and Fouling Tendency of a Coal 042

3.7 Characterization of Coal for Coke 045

3.7.1 Carbonization of Coal for Coke 045

3.7.2 Fluidity or Plastic Properties of Coal by Constant-Torque Gieseler Plastometer (Audibert-Arnu Dilatometer) 045

3.7.3 Expansion and Contraction of Coal by the Sole-Heated Oven 047

3.7.4 Swelling Properties of Coal Using a Dilatometer 048

3.7.5 Free-Swelling Index (FSI) 049

3.7.6 Stability Index for Coke Using the Tumbler Test 051

3.7.7 Metallurgical Coal 051

3.8 Coal Petrography 054

3.8.1 Coal Petrographic Components 054

3.8.2 Preparation of Coal Sample for Microscopical Analysis by Reflected Light- Stopes-Heerlen System 055

3.8.3 Coal Types and Corresponding Coking Properties 056 4 COMMINUTION AND SIZE REDUCTION 059

4.1 Objective of Size Reduction 060

4.2 Energy Requirements for Size Reduction 060

4.3 Principle of Size Reduction and Liberation 062

4.3.1 Reduction Ratio 062

4.3.2 Specific Energy 063

4.4 Unit Operations for Comminution 065

4.5 Size Distribution Analysis 071

4.5.1 Sieve Analysis 072

4.5.2 Rosin-Rammler Equation 073 5 SCREENING, CLASSIFICATION, AND DESLIMING 077

5.1 Screen Efficiency 078

5.1.1 Efficiency of Undersize Removal 078

5.1.2 Efficiency of Undersize Recovery 080

5.2 Mass (Material) Balances 082

5.3 Crushing and Grinding Circuits 086

5.3.1 Open Circuit 087

5.3.2 Closed Circuit 088

5.3.3 Relationship between Em and Er 091

5.4 Types of Crushers Used in Mineral Processing 092

5.5 Unit Operations for Screening, Classification, and Desliming 093

5.6 Classification by Hydrocyclone 095 6 WASHABILITY ANALYSIS 097

6.1 Float-and-Sink Test 098

6.1.1 Heavy Medium Suspensions for Float-and-Sink Tests 098

6.1.2 Float-and-Sink Test Procedures 098

6.2 Washability Data Analysis 099

6.3 Composite Washability Data for Coal 106 7 GRAVITY BASED SEPARATION PROCESSES 109

7.1 Fundamental of Momentum Transport and Settling Velocity of Particles in Fluid 110

7.1.1 Criteria for Viscous Flow (Stokes' Criterion for Small Particles) 110

7.1.2 Criteria for Turbulent Flow (Newton′s Criteria for Large Particles) 112

7.1.3 Allen Equation for Intermediate Flow Region 113

7.2 Equal Settling Terminal Velocity 113

7.2.1 Free Settling 113

7.2.2 Hindered-Settling 114

7.3 Concentration Criteria 115

7.4 Separation by Difference in Settling Rate 116

7.5 Sphericity of a Particle 117

7.6 Unit Operations for Coal Concentration 119

7.6.1 Jig 120

7.6.2 Dense Medium Vessel 125

7.6.3 Dense Medium Cyclone 125

7.6.4 Concentration Table 125

7.6.5 Water-Only Cyclone 131

7.6.6 Spiral Concentrators 133

7.6.7 Hindered-Settling Bed Separators 135

7.6.8 Pneumatic Coal Preparation Process 136 8 PROCESS EVALUATION AND PREDICTING COAL CLEANING RESULTS 141

8.1 Determination of Clean Coal Yield by Product Ash Analysis 142

8.2 Determination of Efficiency and Sharpness of Separation for a Coal Cleaning Unit 143

8.3 Prediction of Coal Cleaning Results 147 9 FROTH FLOTATION OF FINE COAL 149

9.1 Surface and Interfaces of Solid-Liquid-Gas 150

9.1.1 Young′s Equation 151

9.1.2 Dupree′s Equation 152

9.2 Effect of Coal Rank and Mineral Inclusion on Coal Floatability 152

9.3 Parameters Affecting the Rate of Flotation 153

9.3.1 Rate of Flotation in Stirred Tank Cell flotation 154

9.3.2 Pyrite Reverse Flotation Process for Desulfurization 155

9.4 Weathered Coal (Oxidized Coal) 156

9.4.1 Sources of Weathered Coal 156

9.4.2 Characteristics of Oxidized Coal 156

9.4.3 Adverse Properties of Oxidized Coal on Coal Preparation 157

9.4.4 Coal Preparation Methods of Controlling the Effects of Oxidized Coal 157

9.5 Flotation Reagents 158

9.5.1 Effects of Non-Polar Hydrocarbon Oils 158

9.5.2 Common Flotation Reagents Used in Fine Coal Flotation 159

9.6 Flotation Conditioner for Weathered Coal 161

9.7 Calculation of Combustible Material Recovery 162

9.8 Unit Operations for Ultra-fine Coal 163

9.8.1 Stirred Tank Flotation Cell 163

9.8.2 Flotation Column 165 10 DEWATERING, THICKENING, AND DRYING 167

10.1 Introduction 168

10.2 Principle of Filtration (Cake formation in filtration) 169

10.2.1 Filter Cake Resistance, Rc 170

10.2.2 Filtration Equations 171

10.2.3 Methods of Filtration Operations 172

10.3 Filtration Experiment for Determination of Filtration Area 172

10.3.1 Constant Pressure Filtration Experiment 174

10.3.2 Estimation of Filtering Area Required for a Plate and Frame Filter Operation 175

10.4 Continuous Filtration Operations 179

10.5 Centrifugal Filtration 183

10.6 Vacuum Filters 184

10.7 Fluidized-Bed Coal Thermal Dryer 186

10.8 Flocculation and Coagulation 187

10.9 Sedimentation, Thickening, and Clarifying 190

10.9.1 Sedimentation Rate and Thickener Capacity 190

10.9.2 Kynch Method 193

10.9.3 Operating Line 195

10.9.4 High-capacity thickening 197 11 ON-LINE COAL QUALITY MONITORING AND MATERIAL HANDLINGS 199

11.1 X1-LiNX Coal Analyzer 200

11.2 Combined Ash, Moisture and Elementary Belt Analyzer(AM-EBA) 201

11.3 Moisture Meter 202

11.4 Elemental Analyzer 203

11.5 Belt Scale 204

11.5.1 Singe-Station Conveyor Belt Scale 204

11.5.2 Dual-Station Conveyor Belt Scale 204

11.5.3 Multi-Station Conveyor Belt Scale 205

11.6 High Speed Sorting Gate 206 12 PLANT FLOWSHEET DESIGN 207

12.1 Coal Cleaning Circuits Configuration and Plant Flowsheet Design 208

12.2 Solids and Water Balances 215 13 COARSE REFUSE AND TAILINGS MANAGEMENT AND ENVIRONMENT 219

13.1 Tailing Dams 220

13.1.1 Methods of Tailings Dam Construction 220

13.1.2 Construction of Tailing Dam Wall Utilizing Cyclone Underflows 222

13.2 Contaminants from Reagents Used in Processed Plants 223

13.3 Water Balance in Tailings Impoundment 223

13.3.1 Water Gain and Loss in Impoundment 223

13.3.2 Water Reclamation System for Closed-Water Circuit 224

13.3.3 Design of a Settling Basin – An Example 225 14 HOMEWORK, PROJECTS, LABORATORY EXPERIMENTS, AND EXAMS 229

14.1 Homework 230

Homework #1 Coal Resources and Characterization 230

Homework #2 Environmental Impact of Coal Utilization, and Crushing and Comminution 231

Homework #3 Material Balances in Crushing Plant and Grinding Circuit 232

Homework #4 Washability Data and Prediction of Raw Coal Cleaning Results 232

Homework #5 Design Project 233

Homework #6 Flotation of Fine Coal and Oxidized Coal 234

Homework #7 Dewatering and Thickening and Online Quality Monitoring 235

14.2 Laboratory Experiments 236

Laboratory #1 - Preparation of ″representative″ Coal Sample and Chemical Analysis 236

Laboratory #2 - Size Distribution and Analysis 239

Laboratory #3 - Washability Analysis of Coal 241

Laboratory #4 - Froth Flotation 244

Laboratory #5 - Thickener Design 246

14.3 Exams 248

Exam 1 (Close books and notes) 248

Exam 2 (Close books and notes) 249

Exam 3 (Close books and notes) 251

Exam 4 (Open books) 255

Final Exam (Open book) 258 References 263 Subject Index 267

-

数字电子技术

¥36.8¥43.8 -

进步简史

¥11.7¥30.0 -

突发环境事件应急监测案例研究

¥94.7¥128.0 -

自然灾害情景态势推演规则与风险评估方法

¥49.1¥78.0 -

生命周期评价方法与实践

¥132.7¥168.0 -

矿山安全工程

¥51.3¥59.0 -

变电二次安装工实用技术

¥88.3¥128.0 -

铅铋合金冷却反应堆技术

¥125.6¥159.0 -

核动力设备静密封技术

¥211.7¥268.0 -

东北环境史专题研究

¥62.4¥80.0 -

快速认识世界汽车标志与车名

¥32.4¥49.9 -

基于机器学习理论的通信辐射源个体识别

¥52.3¥78.0 -

智能汽车电子与软件:开发方法、系统集成、流程体系与项目管理

¥70.9¥109.0 -

《二手纯电动乘用车鉴定评估技术规范》实施与细则(修订版)

¥36.0¥45.0 -

储能产业政策与典型项目案例解析

¥77.4¥98.0 -

智能金属矿山

¥42.6¥49.0 -

华夏衣裳 汉服制作实例教程

¥104.3¥149.0 -

机械加工基础入门 第3版

¥38.4¥59.0 -

发电厂、变电站二次系统及继电保护测试技术(第二版)

¥60.7¥88.0 -

国际单位制(SI)

¥39.2¥49.0