暂无评论

图文详情

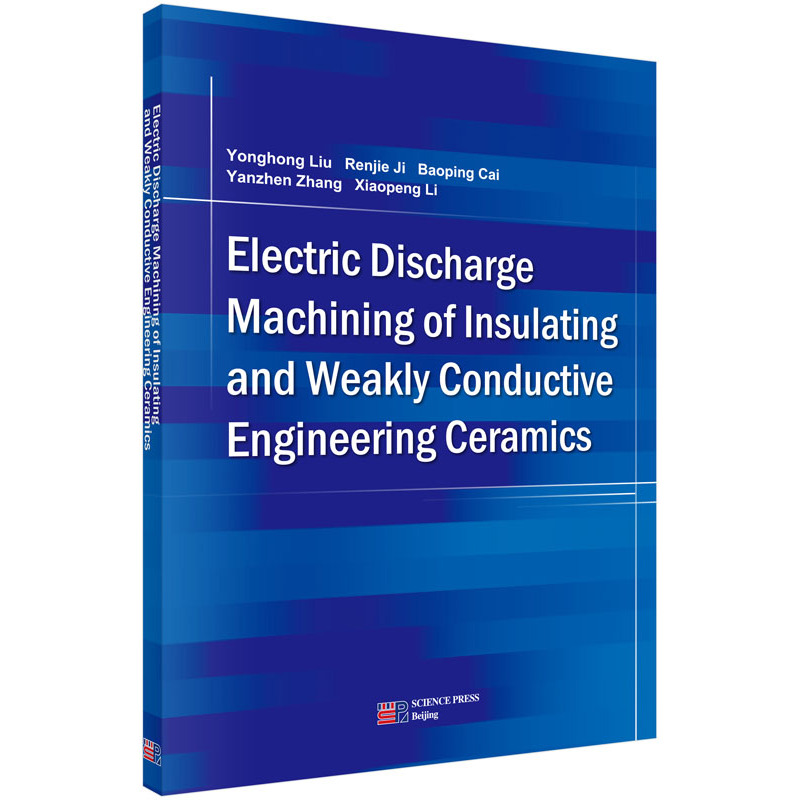

- ISBN:9787030440044

- 装帧:一般胶版纸

- 册数:暂无

- 重量:暂无

- 开本:24cm

- 页数:232

- 出版时间:2015-06-01

- 条形码:9787030440044 ; 978-7-03-044004-4

内容简介

刘永红等著的《绝缘及弱导电工程陶瓷电火花加 工(英文版)》系统论述绝缘及弱导电工程陶瓷电火花 加工相关技术的著作,该著作综合了作者多年来在该 方面的研究成果,主要介绍了绝缘工程陶瓷的电火花 铣削、电火花磨削、高能量电容放电加工等技术,以 及弱导电工程陶瓷的齿电极电火花铣削、端面电火花 铣削、端面电火花铣磨复合加工等技术,并对各种加 工技术的加工机理和工艺规律进行了系统深入的理论 与试验研究,得到了各加工参数对加工工艺性能的影 响规律关系,建立了加工工艺指标与加工参数之间的 数学模型,揭示了绝缘及弱导电工程陶瓷的材料蚀除 机理。

目录

ContentsForewordPrefaceChapter 1 Electric Discharge Milling oflnsulating Engineering Ceramics1.1 Introduction1.2 Principle and characteristics ofED milling1.2.1 Principle ofED milling1.2.2 Characteristics ofED milling1.3 Experiments alo_d discussion1.3.1Effects ofthe pulse duration on the process performance1.3.2Effects ofthe pulseinterval on the process performance1.3.3 Effects ofthe peak current on the process performance1.3.4 Effect of tool polarity on the process performance1.3.5 Effect ofpeak voltage on the process performance1.3.6Effect ofrotational speed ofthe tool electrode on the process performance1.3.7 Effect offeed speed ofthe workpiece on the process performance1.3.8Effect of emulsion concentration ofthe machining fluid on the processperformance1.3.9 Effect ofNaN03 concentration ofthe machining fiuid on the processperformance1.3.10Effect ofPolyvinyl alcohol concentration on the process performance1.3.11Effect offlow velocity ofthe machining fiuid on the process performance1.4Numerical simulation ofsingle pulse discharge machining insulating Al20 3 ceramic1.4.1 Model details1.4.2 Finite element formulations 1.4.3 Results and d:iscussion1.5 ConclusionsRe ferencesChapter 2 Single Discharge Macluning oflnsulating Ceramics Efficiently with High Energy Capacitor2.1 Introduction2.2 Experiments2.2.1 Experimentalprinciple2.2.2 Experimentalprocedure2.3 Results and discussion2.3.1 Effect oftoolpolarity on the process performance2.3.2Effect ofpeak voltage on the process performance2.3.3 Effect ofcapacitance on the process performance2.3.4Effect of current-limiting resistance on the process performance2.3.5Effect oftool electrode feed on the process performance2.3.6 Effect oftool electrode section area on the process performance2.3.7Effect of assisting electrode thickness on the process performance2.4 Microstructure character ofsingle discharge crater oninsulating ceramicsurface2.5 ConclusionsReferencesChapter 3 ElectricaIDischarge MechanicaIGrinding oflnsulating EngineeringCeramics3.1 Introductio3.2 Principle ofEDGSSDE3.3 Formation and function of oxide layer on grinding wheel3.4Formation and filnction ofmetamorphosedlayer on workpiece surface3.5 Analysis ofresidual stresses in EDGSSDE ofengineering ceramics3.5.1 Assumptions3.5.2 Temperaturemodels3.5.3 Residual stresses model3.5.4 Results3.6 Experiments3.6.1 ExperimentaIConditions3.6.2 Results and analyses3.7 ConclusionsRe ferencesChapter 4 ElectricaIDischarge Milling ofWeakly Conductive Engineering CeranucsChapter 5 End Electric Discharge Milling ofWeakly Conductive Engineering CeramicsChapter 6 Electric Discharge Milling and Mecharucal Grinding Compound Machining ofWeakly Conductive Engineering CeramicsChapter 7 High Speed End ElectricalDischarge Milling and Mechanical Grinding ofWeakly Conductive Engineering CeramicsChapter 8 Machining Fluid for Electrical Discharge Machining of Engineering Ceranucs

展开全部

本类五星书

浏览历史

本类畅销

-

港口文化

¥19.2¥60.0 -

黑科技驱动世界的100项技术

¥20.9¥69.8 -

世界桥梁趣谈

¥10.6¥28.0 -

环境保护辞典

¥14.4¥45.0 -

宣纸制造

¥6.4¥20.0 -

电子操作工必读

¥2.3¥8.0 -

检测与计量研究

¥21.0¥70.0 -

ABAQUS 在水力压裂模拟中的应用

¥196.9¥358.0 -

服装结构制图

¥13.3¥39.0 -

人居生态学

¥48.5¥99.0 -

服装制作基本技能

¥4.9¥10.0 -

环境影响评价技术方法基础过关800题(2024年版)

¥45.6¥57.0 -

电工基础

¥6.2¥14.5 -

金属材料力学性能检测技术与应用

¥36.8¥49.0 -

煤矿全员素质提升丛书:煤矿企业从业人员安全生产应知应会手册

¥54.6¥78.0 -

煤矿安全生产应急管理.井工

¥47.6¥68.0 -

3D打印应用技术

¥48.3¥68.0 -

《煤矿安全生产条例》学习辅导教材:含习题及答案解析

¥45.5¥65.0 -

氧化亚氮减排原理与应用

¥75.5¥98.0 -

机电概念设计【MCD】教学工作页

¥26.3¥36.0