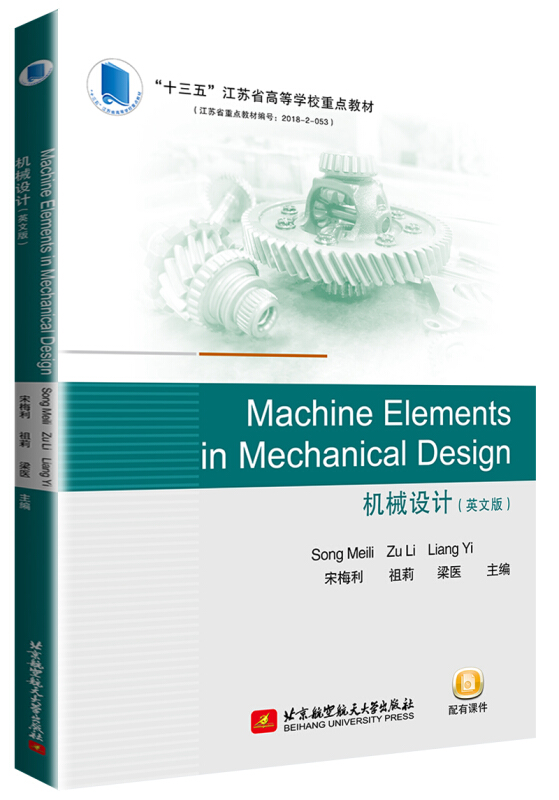

- ISBN:9787512431485

- 装帧:一般胶版纸

- 册数:暂无

- 重量:暂无

- 开本:26cm

- 页数:10,372页

- 出版时间:2020-08-01

- 条形码:9787512431485 ; 978-7-5124-3148-5

本书特色

(1)本书为“十三五”江苏省高等学校重点教材 (2)本书配有课件供读者参考

内容简介

This book is one of the excellent textbooks for colleges and universities of Jiangsu Province in 2018, which is based on the demand for mechanical engineering field in teaching reform. It is designed to be used as the basic course for the undergraduate students in mechanical design. There are fifteen chapters in this book .Its coverage includes introduction;strength of mechanical parts;friction, wear and lubrication;threaded joints;axle and hub connections;rivetings,weldings and bondings;power screws;belt drives;chain drives;gear drives;worm gear transmission;shafts;sliding bearings;rolling-element bearings;couplings, clutches and brakes. Homework problems and projects involving design and analysis provide a basis for the course to follow. At the end, the text is supplemented by a glossary of terms. This book can be used as textbooks for the course of machine elements in mechanical design or a reference for students, teachers and engineers specializing in mechanical engineering.

目录

Chapter 1 Introduction 1

1.1 The Objectives and Tasks of the Course 1

1.2 Basic Requirements and Design Procedures 2

1.2.1 Basic requirements 2

1.2.2 Procedures for mechanical design 4

1.3 Failure Modes and Design Criteria 6

1.3.1 Failure modes of mechanical parts 6

1.3.2 Criteria for mechanical parts 6

1.4 Common Materials and Their Selection Principle of Mechanical Parts 8

1.4.1 Common materials of mechanical parts 9

1.4.2 Materials selection principle 11

1.5 Modern Mechanical Design Theories and Methods 12

Internet Resources 13

Problems 14

Chapter 2 Strength of Mechanical Parts 15

2.1 Introduction 15

2.2 Working Capacity Calculation Criteria for Mechanical Parts 16

2.2.1 Failure form of mechanical parts 16

2.2.2 Working capacity calculation criteria 16

2.3 Common Materials for Mechanical Parts and Their Selections 18

2.3.1 Common materials for mechanical parts 1

2.3.2 Principles for selecting mechanical parts materials 22

2.4 Load and Stress Acting on Parts 24

2.4.1 Classification of load 24

2.4.2 Classification of stress 24

2.5 Strength Calculation 25

2.5.1 Strength of mechanical parts under static stress 25

2.5.2 Fatigue strength calculation of mechanical parts 27

2.5.3 Contact strength of mechanical parts 32

Internet Resources 34Problems 34

Chapter 3 Friction, Wear and Lubrication 36

3.1 Introduction 36

3.2 Friction 37

3.2.1 Dry friction 39

3.2.2 Boundary friction (boundary lubrication) 40

3.2.3 Mixed friction (mixed lubrication) 41

3.2.4 Fluid friction (fluid lubrication) 42

3.3 Wear 42

3.3.1 Typical wear process 42

3.3.2 Types of wear 43

3.4 Lubrication 45

3.4.1 Main properties of lubricants 46

3.4.2 Viscosity law 50

3.4.3 Introduction to fluid lubrication 51

Internet Resources 52

Problems 52

Chapter 4 Threaded Joints 53

4.1 Introduction 53

4.1.1 Thread formation 53

4.1.2 Types and applications of screw 53

4.1.3 Main parameters of the thread 56

4.2 Types of Threaded Joints and Standards 57

4.2.1 Types of threaded joints 57

4.2.2 Standard threaded couplings 59

4.3 Pre-tightening and Anti-looseness of Threaded Joints 61

4.3.1 Pre-tightening of threaded joints 61

4.3.2 Anti-looseness of threaded joints 64

4.4 Strength Calculation for the Single Threaded Joints 66

4.4.1 Strength calculation of loose bolt connections 66

4.4.2 Strength calculation of tight bolt connections 67

4.4.3 Material and allowable stress of threaded couplings 73

4.5 Design and Force Analysis of Bolt Group Connections 75

4.5.1 Structural design of bolt group connections 75

4.5.2 Force analysis of bolt group connections 76

Internet Resources 79

Problems 79

Machine Elements in Mechanical Design Project 82

Chapter 5 Axle and Hub Connections 83

5.1 Key Connections 83

5.1.1 Types and applications 83

5.1.2 Selection and the strength calculation 86

5.2 Spline Connections 90

5.2.1 The type, characteristics and application of spline connections 90

5.2.2 The strength calculation of spline connections 92

5.3 Pin Connections 93

Internet Resources 95

Problems 95

Project 95

Chapter 6 Rivetings,Weldings and Bondings 97

6.1 Rivetings 97

6.1.1 Rivet joints 97

6.1.2 Failure forms and design of rivetings 98

6.2 Weldings 99

6.2.1 Types, characteristics and applications of weldings 99

6.2.2 Failure modes of welding 99

6.2.3 Design of welding parts 100

6.3 Bondings 102

6.3.1 The applications of bondings 102

6.3.2 Adhesive joints 102

6.3.3 Adhesives 103

6.3.4 Comparisons of bondings, rivetings and weldings 104

Internet Resources 104

Problems 104

Chapter 7 Power Screws 105

7.1 Types, Characteristics and Applications of Power Screws 105

7.2 Sliding Power Screws 106

7.2.1 The structure of sliding power screws 106

7.2.2 Design calculation of sliding power screws 107

7.3 Ball Screws Drives 110

7.3.1 Structure types and characteristics 110

7.3.2 Design and calculation of ball screws drives 112

Internet Resources 113

Problems 113

Project 114

Chapter 8 Belt Drives 116

8.1 Types and Characteristics of Belt Drives 116

8.1.1 Working principle and characteristics of belt drives 116

8.1.2 Types and applications of belt drives 117

8.2 Analysis of Belt Drives 118

8.2.1 Force analysis of belt drives 118

8.2.2 Stress analysis of belts 120

8.2.3 Elastic slipping and creeping of belts 121

8.3 Design Calculation of Ordinary V-belt Drives 123

8.3.1 V-belt structures 123

8.3.2 Standard for ordinary V belts 124

8.3.3 Basic rated power of single V belt 125

8.3.4 Design steps and methods of V-belt drives 127

8.4 Design of V-belt Pulleys 132

8.4.1 Design requirements for V-belt pulleys 132

8.4.2 Materials of V-belt pulleys 132

8.4.3 Structure dimension of V-belt pulleys 132

8.5 Tension and Maintenance of Belt Drives 136

8.5.1 Tension of belts 136

8.5.2 Belt maintenance 137

8.6 Introduction of Other New Belt Drives 137

8.6.1 High speed belt drives 137

8.6.2 Toothed timing belt drives 138

8.6.3 V-ribbed belt drives 139

Internet Resources 139

Problems 139

Project 140

Chapter 9 Chain Drives 142

9.1 Introduction 142

9.2 Structure of Chains 143

9.2.1 Roller chains 143

9.2.2 Silent chains 145

9.3 Structure and Material of Sprockets 146

9.3.1 Basic parameters of sprockets 147

9.3.2 Sprocket tooth profile 148

9.3.3 Structure of sprockets 149

9.3.4 Material of sprockets 149

9.4 Geometric Parameters of Chain Drives 150

9.4.1 Number of pitches 150

9.4.2 Center distance 151

9.5 Motion Characteristics of Chain Drives 151

9.5.1 Kinematics of chain drives 151

9.5.2 Dynamical loads of chain drives 153

9.6 Load Analysis of Chain Drives 154

9.7 Failure Modes and Carrying Capacity of Chain Drives 155

9.7.1 The failure modes of chain drives 155

9.7.2 Carrying capacity of chain drives 156

9.8 Chain Drives Design 158

9.8.1 Design the pitch and number of strands 158

9.8.2 Design the number of teeth in two sprockets and speed ratio 160

9.8.3 Design the number of links and center distance 161

9.8.4 Design the structure of the small sprocket 161

9.9 Layouts, Tension and Lubrication of Chain Drives 162

9.9.1 Layout of chain drives 162

9.9.2 Tension of chain drives 162

9.9.3 Lubrication of chain drives 163

Internet Resources 165

Problems 166

Project 167

Chapter 10 Gear Drives 168

10.1 Introduction 168

10.2 The Failure Modes and Design Rules of Gear Drives 170

10.2.1 Failure modes of gears 170

10.2.2 Design criteria 173

10.3 Materials and Heat Treatment of Gears 174

10.3.1 Steel 175

10.3.2 Cast iron 176

10.3.3 Bronze 176

10.3.4 Nonmetallic material 176

10.4 The Calculated Load for Gear Drives 176

10.4.1 Application factor 177

10.4.2 Dynamic factor 177

10.4.3 Axial load distribution factor 178

10.4.4 Load distribution factor across teeth 182

10.5 Strength Calculation of Standard Spur Gears 183

10.5.1 Force analysis 183

10.5.2 Calculation of spur teeth bending fatigue strength 184

10.5.3 Calculation of spur teeth contact fatigue strength 186

10.5.4 Tips for gear strength calculation 189

10.6 Design Parameters, Permissible Stress and Accuracy Choice of Gears 190

10.6.1 Design parameters 190

......

-

电工电子技术及应用(第2版)

¥24.9¥39.8 -

新编实用化工产品丛书胶黏剂:配方.工艺及设备/新编实用化工产品丛书

¥37.0¥48.0 -

世界桥梁趣谈

¥10.5¥28.0 -

电子技术与应用

¥32.4¥49.0 -

新能源汽车高压电用电安全实训

¥31.9¥49.0 -

童装结构设计与制版

¥28.9¥49.0 -

电工基础与技能

¥21.2¥42.0 -

交通与运载工程学科:前沿技术发展与科学问题(第一册)

¥110.0¥200.0 -

信号与系统——使用MATLAB分析与实现(第2版)

¥43.5¥59.0 -

现代工程图学(第4版·修订版)

¥35.2¥59.0 -

数据通信与计算机网

¥35.7¥55.0 -

材料科学基础(第3版)

¥37.5¥58.0 -

公路工程质量检验评定标准

¥33.4¥90.0 -

黄河400问

¥10.8¥28.0 -

中国传统酿造酒醋酱

¥38.1¥128.0 -

珠宝赏鉴-奢侈品私享家

¥31.7¥128.0 -

全面推行河湖长制典型案例汇编(2024)

¥60.8¥88.0 -

内弹道理论与装药技术

¥120.0¥160.0 -

2022年中国生态环境质量报告

¥102.9¥139.0 -

射频干扰袖珍手册

¥20.4¥29.0